General Information

The following information provides general equipment and service information that will help you to use this manual to properly repair and maintain the treadmill.

Model Numbers

The product model number is a six digit alphanumeric code "AAAXXX" containing the following components. Use the Product Model Number table to interpret the product number code.:

Product model number format: "AAAXXX"

- "AAA" - three alpha character product type designator

- "X" – 1 digit numeric product line designator

- "X" – one digit numeric console type designator

- "X" – one digit numeric feature level designator

Example

Product model number: TRM833

- TRMTreadmill – Treadmill

- 8 – Experience Line

- 3 – P30 console

- 3 – Fixed ramp

Product Model Number Table

| PRODUCT TYPE | PRODUCT LINE | CONSOLE | FEATURE LEVEL | |

|---|---|---|---|---|

| TRM: treadmill EFXElliptical Fitness CrossTrainer: elliptical AMTAdaptive Motion Trainer: AMT UBKUpright Bike: Upright RBKRecumbent Bike: Recumbent |

8-Experience, Premium 7-Experience, 6-Assurance, Standard 4-Precision, Consumer 2-Energy, Consumer |

8-P80, P82 6-P62 3-P30, P31 2-P20 1-P10 |

7 | EFX: Fixed Ramp/Moving Arms |

| 5 | TRM: High Speed/Decline AMT: Moving Step Height EFX: Moving Ramp/Moving Arms |

|||

| 3 | TRM: Fixed Ramp

AMT: Fixed Step Height EFX: Moving Ramp/Fixed Arms |

|||

| 1 | EFX: Fixed ramp/Moving Arms | |||

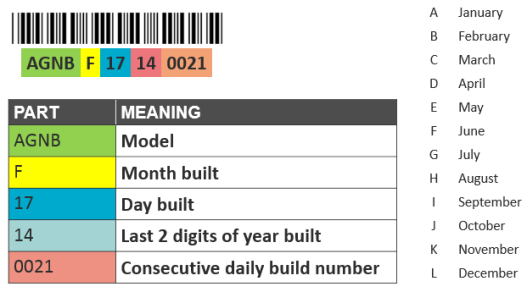

Serial Numbers

About

The serial number uniquely identifies each machine. The serial number is an alphanumeric code comprised of a four character model designator, a 1 letter build month code, a 2 digit day built, a 2 digit year built and a four digit consecutive daily build number.

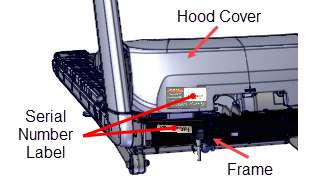

Serial Number Label Location

The serial number label is located on the hood and frame.

|

|

Note: Always use the frame serial number label to verify the machine serial number. Do not use a label attached to a plastic cover, the cover may have been replaced from a different machine. |

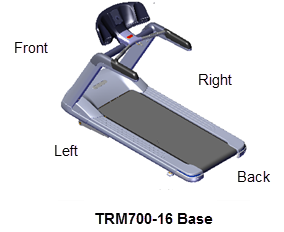

The equipment orientation (front, right, left, & back) is referenced to an exerciser standing on the machine facing the console.

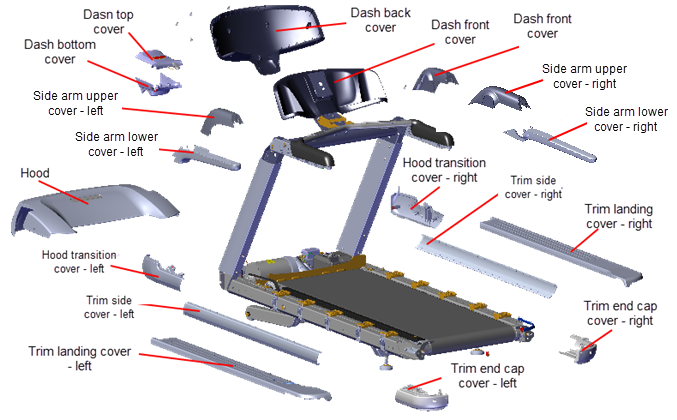

Equipment cover and access panel locations.

For cover removal and installation, see Covers and Panels Replacement.

Tools and supplies required to complete the machine service and repair.

Tools

| • US and Metric Hex Key set | • Standard straight slot tip screw drive set |

| • US and Metric socket set | • Philips tip screw driver set |

| • Us and Metric wrench set | • US & metric Allen wrench set |

| • Cutters | • 7/16” Allen key, socket mounted |

| • Rubber mallet | • Pliers |

| • Tape measure /Straight edge ruler | • Inner and outer snap ring pliers |

| • DVM meter | • TorqueTorque is a measure of the force that can cause an object to rotate about an axis. Bolt/nut example: 5 nM torque is equivalent to 5 newtons of force applied one meter from the center of the bolt, 6 ft-lb is equivalent to 6 lb of force applied 1 foot away from the center of the bolt. Wrenches: 9 in lbs to 100 in - lbs (83 ft-lbs) |

| • ACAlternating Current: electric current which periodically reverses direction between positive and negative polarity. Clamp-on averting current meter | • DVM Multimeter |

| • Belt tension gauge – OTC Tools Model #: 6673 | • Drive Belt tension Gauge (Kent-Moore BT-33-73-F |

| • 2 Running belt tension gauges (Precor PN: PPP000000020007101) | • Compatible HR chest strap or Polar HRM simulator xmitter (Precor PN: PPP000000020045101) |

| • 12 " wonder bar | • Vacuum cleaner (recommend ESD safe model) |

| • ESD wrist strap |

Supplies

| • Super Lube Gel with Teflon by Permatex | • Cleaning rags |

| • Mobil 1, NLGI 2 Teflon Synthetic Grease | • Cleaner Degreaser (see ) |

| • Loctite 243 Blue Medium Strength Threadlocker | • Cable ties (1- 3/4", 3", 4" lengths) |

Fastener Torque Specification

System component fastener torque specification:

| System Component | Specification |

|---|---|

| RFRadio Frequency: Identifies electromagnetic signals with frequency spectrum between the 3 kHz (3,000 hertz) to 300 GHz (300 billion hertz) range. coax connector | 2.4 in-lbs (0.271 Nm) |

| Display mounting fasteners | 180 in-lbs (20 Nm |

| Set screws | 300 in-lbs (34 Nm) |

| Plastite screw fasteners | 20 in-lbs (2.3 Nm) |

| Flathead screws | 25 in-lbs (2.8 Nm) |

| Deck front fasteners | 27-33 in-lbs (3.1-3.7 Nm) |

| Deck rear fasteners | 50-55 in-lbs (5.6-(6.2 Nm) |

| Lift Motor Calibration gap | 1 1/8 in - 1 3/16 in (2.8 cm - 3.0 cm) |

Belt Tension Specification

.Belt tension specification:

| System Component | Specification |

|---|---|

| Drive Belt Tension New Belt(1) | 100-120 lbs (45-54 kgs) |

| Drive Belt Tension Used Belt(1) | 80-90 lbs (36-41 kgs) |

| Drive Motor fasteners | 204 in-lbs (17 ft-lbs, 23 N-m) |

| Ammeraal brand running belt tension (gauge/percent) | (Undefined variable: Specifications.TRM14TRM800 version 2 treadmills mfg. dates 2014 and later.-AmeraalRunBeltTension)(2) |

| Forbo brand running belt tension (gauge/percent) | 3.55 (0.55%)(2) |

| (1) New belt tension applies to new belt first time installations. Used belt tension applies to reinstalling an existing belt or re‑tensioning an existing used belt. (2) Referenced to 3.0 (0.0%). |

|

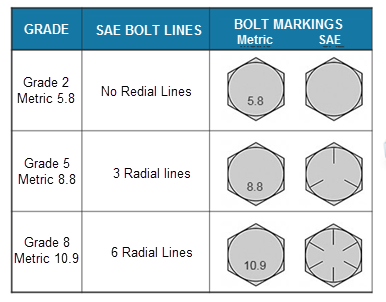

Bolt grade markings are used to categorize bolts according to the bolt material, manufacturing process, and mechanical properties.The grade of the bolt is stamped on the head of the bolt.

US SAE bolts: The bolt grade markings are determined by the number of the lines stamped on the head of the bolt. The number of lines is always two less than the grade of the bolt. Count the lines, add two, and you can determine the grade of the bolt.

Metric bolts: On metric bolts, the bolt grade is identified by a bolt grade number stamped on the head of the bolt.

|

|

CAUTION: Always replace bolts with the same grade bolt. If you don’t know the grade of the replacement bolt – DO NOT USE THE BOLT. |

Bolt Grade Markings Chart

Example bolt grades used on Precor equipment (may not represent all bolt grades). Always match the replacement bolt grade marking to the removed bott grade marking.

|

|

IMPORTANT: Always purchase OEM replacement parts and hardware from Precor. If you use parts not approved by Precor, you could void the Precor Limited Warranty. Use of parts not approved by Precor may cause injury. |

There is a copy of the parts Exploded View Diagram and Parts Identification List included in the Parts Exploded View Diagram & Parts List chapter that you can use as a quick reference. It is recommended that you go to the servicer partners ![]() Precor Connect (or Precor Connection) website to view the most current parts information including the Exploded View Diagram and Parts Identification List.

Precor Connect (or Precor Connection) website to view the most current parts information including the Exploded View Diagram and Parts Identification List.

-

Precor Connect Partner website

Precor Connect Partner website

Exploded View Diagram and Parts List, see Parts Exploded View Diagram & Parts List.

Only use products from the following list of approved lubricants:

| Lubricant | Description |

|---|---|

| Grease |

Use only NLGI class 2 PTFE synthetic grade grease. Use of unapproved lubricants may void the product warranty. Recommended brands (or equivalent): • Mobil 1® synthetic grease • Super Lube® with Teflon |

|

|

CAUTION: Do not use petroleum based lubricants on mechanical components such as the lift, as this may result in degradation of nylon gearing mechanisms. Use only synthetic lubricants such as "Super Lube with Teflon" or "Mobile One Synthetic" grease (RED). |

|

|

CAUTION: Do not apply any lubricants or wax to the deck and belt. Do not use Wax Blast, silicon sprays, or other applied lubricants. The use of these lubricants will quickly degrade the low-friction surface of the deck. |

Only use the following approved cleaning products to safely clean and prevent damage to the machine surfaces.

Approved Cleaning Products:

- General Equipment Surfaces:

- 1 part mild soap to 30 parts water (recommend Simple Green® cleaner or equivalent).

- Athletic equipment cleaner, 9x7 pre-saturated wipes (ATHLETIX PRODUCTS).

- Enivir O Safe oxygen enhanced cleaner or Enviro Safe glass and multitask cleaner concentrate.

- Consoles and PVSPersonal Viewing System display.: a diluted solution of one part 91% Isopropyl alcohol to one part water.

Cleaning Procedure

- Wipe down equipment using a soft lint-free cloth using only the recommended cleaning solution. Always spray cleaning solution directly onto the cleaning cloth and not directly onto the equipment surface to avoid equipment damage due to excessive moisture.

|

|

CAUTION: Do not use acidic cleaners and do not spray directly onto the equipment surfaces. |

- Rinse surfaces using a clean lint-free cloth dampened with water only.

- Then completely dry with another clean lint-free cloth.

This machine is an externally powered unit that requires the facility to provide good quality input power that satisfies the machine specified power requirements.

Equipment Operating Power Specification

- Nominal 120 VACvoltage in an alternating current circuit models

- Operating voltage: 90 VAC to 132 VAC.

- AC frequency range: 47 - 65 HzThe hertz (symbol: Hz) is the derived unit of frequency in the International System of Units (SI) and is defined as one cycle per second.

- Nominal 240 VAC Models

- Rated Operating voltage: 180 VAC - 264 VAC.

- Frequency: 47- 65 Hz

Facility Input Power Requirements

The facility must provide a good quality stable power signal (not fluctuating or intermittent) to insure performance and trouble tree operation.

Individual branch circuit requirement (US and Canada installations)

Each Precor treadmill must be connected to a separate 20 amp individual branch circuit outlet. No other devices can be connected to the same circuit outlet except for one optional PVS (Personal Viewing System) display if installed.

- Individual branch circuit: An individual branch circuit provides a hot conductor and neutral conductor to a receptacle. The conductors must not be looped, "daisy-chained", or connected to any other conductors or receptacles. The circuit must be grounded according to NEC guidelines or local region electric codes.

|

|

CAUTION: All NEC (National Electric Code) guidelines or local region electric codes must be complied with. |

Plugs and Outlets (US and Canada installations)

US and Canadian installations require 20A current rated power outlets.

Verifying 20 Amp outlet receptacles

You can visually identify a 20A from a 15A rated outlet receptacle by the different style outlet sockets. Make sure the facility wall outlets are the 20A style outlet receptacles.

|

|

CAUTION: DO NOT use 20A to 15A power cord adapters to plug the equipment power cord into a 15A wall outlet. |

20 Amp rated plugs and outlets

| Country | Equipment Voltage | Outlet/PlugDevice power cord connector or electrical cable male connector that is inserted into an electrical receptacle "outlet" (also called the plug-in). Type |

|---|---|---|

| US & Canada | 120 VAC: 50/60 Hz | NEMA 5-20R/5-20P |

| US & Canada | 240 VAC: 50/60 Hz | NEMA 6-20R/6-20P |

Console and PVS Display Power Requirements

LED consoles (P10, P30, P30i and P31)

LED consoles are powered by the machine and do not require an external power supply.

Touchscreen consoles (P62, P80, and P82)

Touchsceen consoles use an AC/DCDirect Current: electrical current that only flows in one direction. power adapter to supply the console input power:

AC/DC adapter power specification:

- Input voltage: 100v-240v

- Output power rating: 60W/12Vdc/5A

Powered Machines (Treadmill):

On powered machines, the power adapter is hardwired to the machine input power circuit.

Self-Power Machines (EFX, AMT, UBK/RBK bikes)

On self-powered machines, the AC/DC power adapter is plugged into the facility wall outlet. Up to ten consoles can be connected to the same 20 amp branch circuit. Only touchscreen consoles can share the same branch circuit, no other devices can be connected to this circuit.

PVS (Personal Viewing System) display

PVS displays use an AC/DC power adapter to power the display.

- On treadmills, the PVS display can be plugged into the same individual branch circuit outlet as the treadmill.

- On self-powered equipment, up to 10 PVS displays can be connected to the same 20A branch circuit. No other devices except PVS displays can be connected to this circuit.

PVS display power: 43W max

AC/DC adapter specification:

- Input voltage: 100v-240v

- Output power rating: 60W/12V/4.17A or 4.2A

Cable TV "CATV" RF input signal power requirements

For touchscreen (P62, P80, and P82) consoles or PVS displays, there is a minimum RF input power requirement to properly supply CATVCable Television (aka Community Access Television) is a system of transmitting television programming to consumers via radio frequency (RF) signals transmitted through coaxial cables signal to the consoles.

- Analog video power: +5 dB1) DB or DBR: treadmill dynamic break resistor 2) Decibel (dB): In electronic systems, the decibel (dB) is a logarithmic unit of measurement used to express the system power gain (+dB) or loss (-dB) in decibels (dB). dB (power) = 10Log Pout/Pin) or, in terms of voltage, dB (power) = 20Log (Vout/Vin). to +10 dB RF power with a +40 dB minimum channel to noise ratio (at each console).

- Digital RF power: -5 dB to 0 dB (at each console).

For MYE displays.

- Analog video power (at each display): - 30 dB to +20 dB RF power with a (+40 dB C/Ncarrier-to-noise ratio: The ratio of power in an RF carrier to the noise power in the channel. CNR is defined as the ratio of the received modulated carrier signal power C to the received noise power N after the receiver filters: in terms of power: CNR = C/N, in terms of decibles CNR(dB) = 10Log(C/N) = C(dBm) – N(dBm). (Channel to Noise ratio).

- Digital RF power (at each display): -5 dB to 0 dB.

Using an RF wall outlet

If a wall RF outlet is used to power several consoles in series for a row of equipment there is a minimum RF power requirement at the outlet of +35 dB at +40 dB minimum channel to noise ratio for analog video and a +25 dB for Digital video. RF signal strength of +35 dB can power 17 to 19 consoles in a single row when properly tapped out.

Ethernet (LAN) input signal requirements

Precor recommends a dedicated CAT6 Ethernet feed to each equipment location.

Communication Requirements:

- 512Kb/s up

- 5-10Mb/s down

- Switch Ports: 80, 123, 443

Touchscreen (P62, P80, and P82) console Preva PBSPreva Business Suite communication protocol

The touchscreen consoles use a security token for communication to the Precor servers. The security token is a hash string that is sent with every API call from the FE’s to the Amazon Cloud. The security token originates after the equipment is registered at the location. The console issues a ‘Call’ which returns the registration token and the fitness equipment URL. Every event after that uses the URL and the token to validate/authenticate communication with the Amazon servers and Preva Business Suite (PBS).

All communication with Precor servers is currently done via outgoing (originating from the console) HTTPS sessions. The console utilizes NTPNetwork Time Protocol (NTP) is a networking protocol for clock synchronization between computer systems over packet-switched, variable-latency data networks. to set its clock and for synchronization. At no time is Precor connecting to the customers facility network to "push" any data. The console initiates all data requests.

.

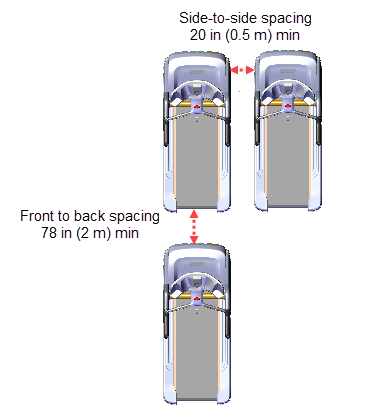

The minimum side to side spacing between treadmills is 20 in (0.5 m) and the minimum front to back spacing is 78 in (2 m).